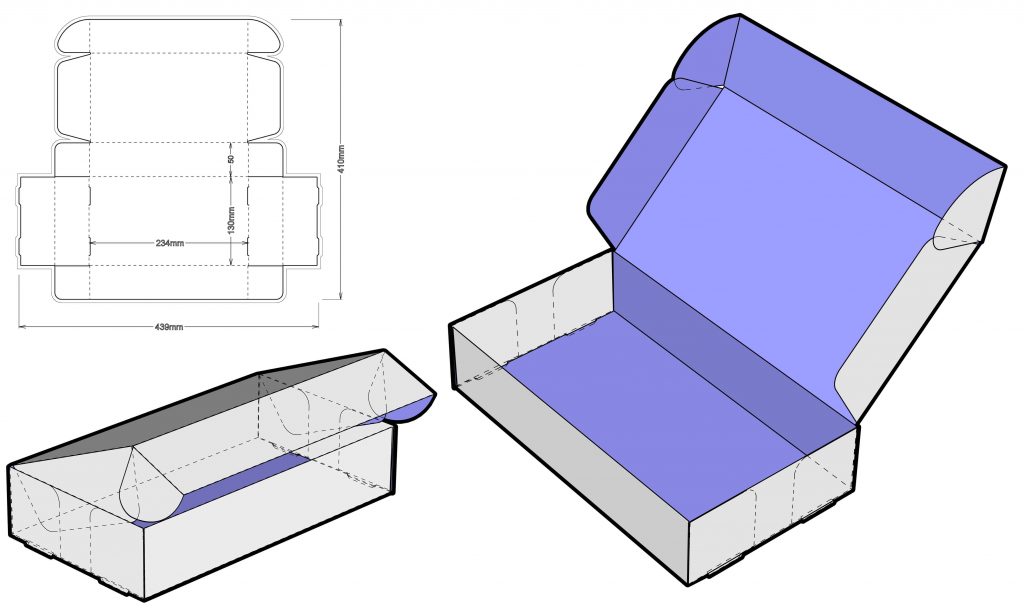

“Die cutting” is the process by which labels get their shape, and the die-cut lines are parts of a package that fold and crease.

Custom die cut inserts act as an additional component to your package that can be removed. They can also be made using a variety of materials: paper, cardboard, plastic, matte, and more.

Complete Packaging Solutions in Brookville, Indiana, can explain what custom die cut insert options are available for your product!

Custom cardboard inserts

Sturdy, stable, and easily shaped to fit your unique design, cardboard inserts can be incredibly cost-effective and made to fit the contours of your product.

Custom foam Inserts

One of the best ways to keep fragile, expensive items safe and sound during shipment is to insert a custom die-cut foam insert. Foam inserts aren’t just lightweight. They provide good insulation from heat or extreme temperature change.

Like all die-cut inserts, you can fully customize them to meet your exact specifications (size, shape, color, contour, thickness, etc.).

Cardstock paper inserts

A lighter, albeit less impact-resistant, option for a custom die-line insert is to use cardstock paper material.

Custom corrugated inserts

Corrugated cardboard inserts are simple and realistic, offering even greater levels of security and structural support to your product.

The primary goal for all inserts is to better organize the products in your package and to make the most out of the size and space of your core package design.

Precise cuts and creases inform how customers will interact with your package once it reaches their hands. Strategic and well-thought-out design is a large part of enhancing the “unpackaging experience” that is so crucial to your business’s brand and image.

Kraft paper inserts

Kraft paper inserts are an incredibly cost-effective option for organizing and sorting the products within your package. They do not offer the same level of impact resistance seen by other inserts (corrugated cardboard or foam).

No matter which die-cut insert option you choose from, you can rest assured that it’s incredibly easy to ship and offers an added layer of protection to your product.

How Exactly are Custom Die Cut Inserts Created?

Packaging companies use a custom die cut machine to leverage automation and digital technologies to generate custom die cuts at a rapid pace.

There are various types of die cutting machines used by companies.

At CPS, we use a flat-bed die cutter which has two parallel platens that exert pressure on a steel rule die.

Let CPS Handle Your Custom Packaging From Start to Finish!

Contact us today to get turnkey packaging solutions. We don’t just design eye-catching packages for short and long run times, but our team will even package and ship your product to customers. Call: (765) 547-1300.